- Jaw Crusher Spares

- Symons Jaw Crusher Spares

- Metso Jaw Crusher Spares

- Sandvik Jaw Crusher Spares

- Cone Crusher Spares

- Symons Cone Crusher Spares

- Metso Cone Crusher Spares

- Sandvik Cone Crusher Spares

- Gyratory Crusher Spares

- Symons Gyratory Crusher Spares

- Metso Gyratory Crusher Spares

- Machine Bronze Parts

- Auto Water Pump Fittings

OEM Customized Investment Casting/Lost Wax Casting Stainless Steel Hardware Pipe Fittings

Basic Info

| Model NO. | OEM |

| Surface Roughness | Ra 0.8-Ra 6.3 |

| Machining Tolerance | up to +/- 0.1mm, According to Customer′s Drawing |

| Standard | JIS&Bsw&ANSI&GB&DIN |

| Certification | CE, ISO 9001:2008 |

| Business Type | Manufacturer |

| Services | OEM/ODM |

| Sample Leading Time | 25-35days |

| Factory Tour | Available |

| Delivery Time | 30-50days |

| Wax Type | Middle Temperature Wax |

| Machining Process | CNC Finishing Process |

| Weight | 0.05~50kgs/Piece |

| Loading Port | Tianjin |

| MOQ | 50 Kg |

| After Sale Service | Order Weekly Updated |

| Quality Control | Ipqc, Fqc |

| Product Application | Water/Oil/Gas/ Various of Corrosive Midia |

| Keyword | Hardware, Casting |

| Trade Term | EXW/Fob/CIF |

| Transport Package | Plastic Bag+Carton+Pallet |

| Specification | As Customer′s Requirement |

| Trademark | Junya |

| Origin | China |

| HS Code | 8433909000 |

| Production Capacity | 1000 Tons/Year |

Product Description

Product Display

Customized Stainless Steel Investment Casting Pipe Fittings

Product Description

| Name | OEM Stainless Steel Investment Casting Pipe Fittings |

| Material | Stainless Steel 304,316 etc, |

| Designs | 1.As per the customer's drawings |

| 2.As per the customer's samples | |

| Surface treatment | 1. Pickling |

| 2. Passivation or/and as per clients' requirement | |

| Service | OEM and ODM service available |

| Products | All kinds of stainless steel casting: include pipe fitting, ball valve, automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts, and furniture parts so on |

| Inspection: | 1.Dimension report |

| 2.Material certification | |

| Packing: | Export carton and fumigation wooden pallet |

Casting Detail

Main Material | Stainless Steel |

| Process | Investment Casting, Lost Wax Casting, Silica Sol Casting. Water Glass Casting, Die Casting |

| Casting Tolerance | CT4-CT6 (GB/T 6414),CT7-CT9 (GB/T 6414) |

| Standard | AISI, ANSI, ASTM, JIS, GB, ISO, DIN, etc. |

| Certificate | TS16949, SGS, ISO, or To Be Tested by a Third Party as per Clients' Requirement |

| Machining | Tapping, Milling, Grinding, Drilling, CNC Machining |

| Tolerance | +/-0.02mm or as per Clients' Requirement |

| Surface Treatment | Polishing, Mirror Polishing, Electro Galvanizing, Sandblasting, Shot blasting |

| Heat Treatment | Quenching and tempering, Annealing, Normalizing |

| Casting Roughness | Ra 1.6-Ra12.5 |

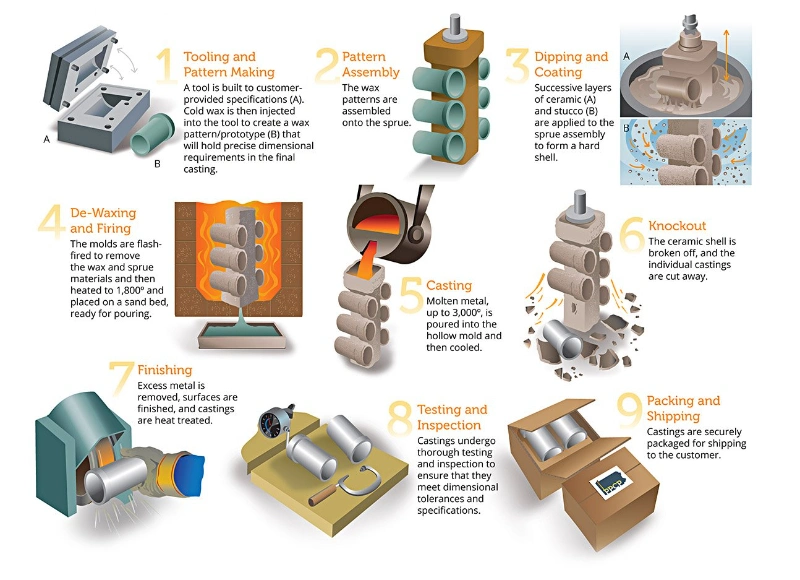

Advantages of Investment Casting

- Investment casting can achieve very thin-walled parts with complex shapes.

- Very accurate, even net shape with precise dimensional casting

- Excellent surface finishes save machining and finishing.

- Ferrous and nonferrous metals, as well as duplex alloys, can be used.

- Investment casting can be quite economical over repeat runs.

Investment Casting/ Lost Wax Casting

When To Use Investment Casting

√ External shaping and tight tolerances exist√ Parts are shaped or non-symmetrical with fine detail√ Multiple and/or intricate internal passageways in design√ Dimensions are small to medium, typically under 1,000 lbs./454 kg√ Excellent as-cast surface finish is required√ Wall thickness is too thin for sand casting√ High upfront tooling costs relative to sand casting are acceptable√ Low volume allows printed patterns to replace upfront tooling√ Ongoing tool maintenance costs are not desired√ Machining of internal passageways is not possible

Company Profile

Hebei Junya Precision Machinery Co. Ltd. (the manufacturing arm of Tianjin Junya Precision Machinery) is a high-tech enterprise combining designing, tooling developing, casting, machining, surface treatment, inspection, sales, and service all together. Founded in 2017 in Huanghua City, Hebei Province, Junya covers an area of more than 5,000 square meters.

Our extensive experience in investment casting / lost- wax casting enables us to provide reliable casting products to clients.

We have been focusing on investment casting / lost wax casting for years, and have accumulated extensive industrial experience, especially in the technological process.

With a massive research & development environment, Junya has utilized market-leading technology and introduced various types of advanced equipment to ensure the stringent quality of products.

In recent years, our products have been widely recognized by professional certification authorities and, more importantly, the market.

Packaging & Shipping

We provide reliable packaging and transportation solutions to secure the safe arrival of goods. Customized packaging or transportation solutions are available as per the requirement of clients.

Buyer Feedback

FAQ

Q1: How long is the lead time of your products?

A: It depends on order quantity, production difficulty of each specific kind of product, etc. Normally, samples can be delivered within 15 days.Q2: Do you provide samples? Is it free or extra?

A: Yes, samples are provided for free, and the clients need only pay for the shipment. Q3: What is the MOQ of your products?

A: It depends on the specific kind of the product, and is negotiable. Q4: Where is your factory?

A: Our factory is located in Hebei province, which is in North China, close to both Beijing and Tianjin with convenient transportation. Q5:What materials/information are needed to submit a quotation?

A: Drawing or Sample, together with relevant information, such as Quantity, Weight, Material. Q6:What if we do not have a drawing?

A: In this case, we can either duplicate your sample or make a drawing according to the specifications provided for your confirmation.