Category

- Jaw Crusher Spares

- Symons Jaw Crusher Spares

- Metso Jaw Crusher Spares

- Sandvik Jaw Crusher Spares

- Cone Crusher Spares

- Symons Cone Crusher Spares

- Metso Cone Crusher Spares

- Sandvik Cone Crusher Spares

- Gyratory Crusher Spares

- Symons Gyratory Crusher Spares

- Metso Gyratory Crusher Spares

- Machine Bronze Parts

- Auto Water Pump Fittings

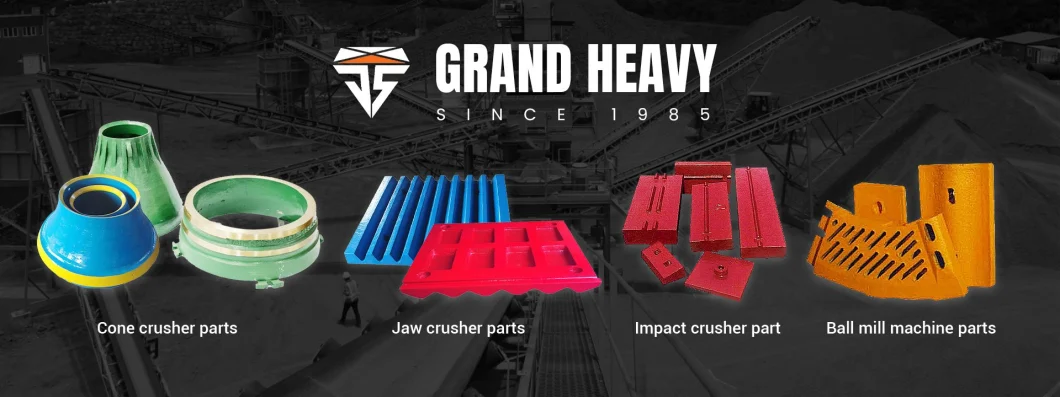

Factory Direct Sales Telsmith Cone Crusher Wear Parts Cedarapids Cone Crusher Spares

Factory Direct Sales Telsmith Cone Crusher Wear Parts Cedarapids Cone Crusher Spares Product Description Cone Crusher Sp

Basic Info

| Model NO. | Cone Crusher Parts |

| After-sales Service | Available |

| Warranty | 12 Months |

| Certification | ISO 9001:2000, ISO 9001:2008 |

| Standard | GB, ASTM |

| Surface Treatment | Polishing |

| Manufacturing Process | Casting |

| Material | Alloy Steel |

| Transport Package | Export Packing |

| Specification | 14MN 18MN 22MN |

| Trademark | Grand Heavy |

| Origin | China |

| HS Code | 8474900000 |

| Production Capacity | 20000tons/Year |

Product Description

Factory Direct Sales Telsmith Cone Crusher Wear Parts Cedarapids Cone Crusher Spares

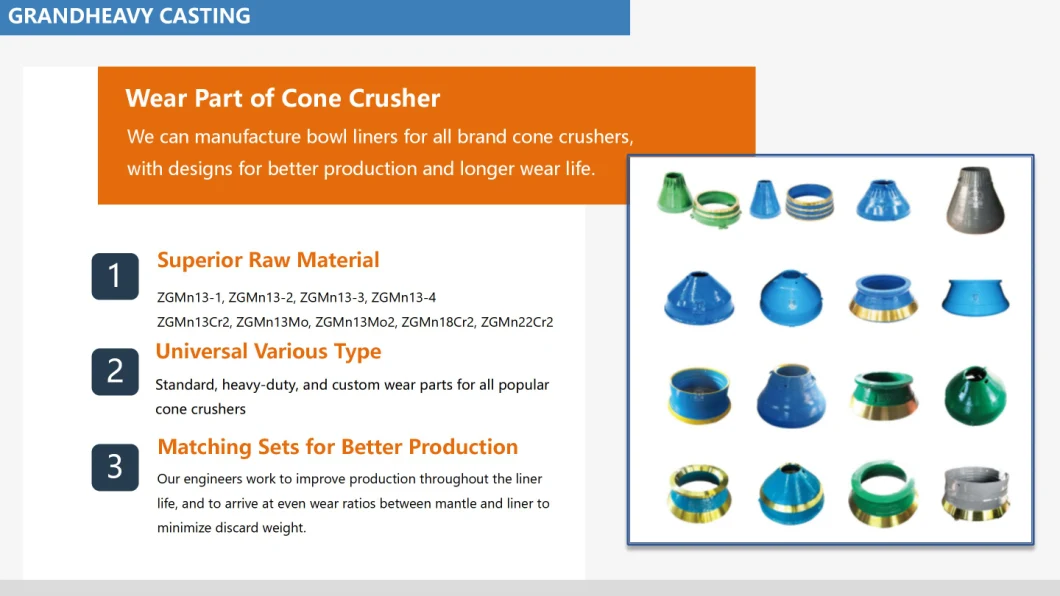

Product DescriptionCone Crusher Spare Parts Bowl Liner and Mantle for Telsmith

Product Name: Cone crusher parts/Concave/Mantle/Bowl liner

Applications: Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

Product Benefits:Compared with the general market products, our products smooth surface, accurate dimensions , high wear resistance and longer life. Direct sales by the company foundry, cost-effective products.

Main Features:

| Competitive products: | Good quality with reasonable price |

| Material: | High manganese and customised materials |

| Use: | We can supply almost crusher parts |

| Quality: | ISO9001 &TS and CE certification |

Available Bowl Liners of Crusher Brand

| Cone Crusher Parts | |||||||||

| SANDV1K | NORDBERG | TEREX | TELSMITH | SYMONS | KUE-KEN(Brown) | SVEDALA | POWERSCREENMAXDRAK | TEREX PEGSONMAXTRAK | |

| CH420 | HP100 | GP100S | RC36 | 24'' | 2' | CT28'' | H22'' | 1000 | TC1000 |

| CH430 | HP200 | GP200S | RC45 | 36'' | 3' | CT750 | H200 | 1000SR | WC1000 |

| CH440 | HP300 | GP300S | RC45-II | 38'' | 4' | CT36'' | H2000 | 1300 | 1000SR |

| CH660 | HP400 | GP500S | RC54 | 44'' | 4800 4 1/4' | CT40'' | H36'' | 1500 | TC1300 |

| CH870 | HP500 | GP100 | RC54-II | 48'' | 5100 5 1/2' | CT1000 | H3000 | WC1300 | |

| CH880 | HP700 | GP200 | RC60 | 52'' | 7' | CT51'' | H45'' | 1500 | |

| CH890 | HP800 | GP300 | RC66 | 66'' | 36'' | CT130 | H4000 | ||

| CH895 | HP3 | GP550 | RC45-III | 48'' | H6000 | Pegson | Extec X SBS | ||

| CS420S2800 | HP4 | GP11 | MVP280 | 66'' | H8000 | 700 | X38 | ||

| CS430S3800 | HP5 | G49 | MVP380 | S36'' | 900 | X4 | |||

| CS440S4800 | HP8 | G108 | MVP450 | S2000 | 1000 | ||||

| CS660S6800 | MP800 | G412 | MVP550 | S3000 | 1300 | ||||

| CS820S8800 | MP1000 | G612 | S4000 | 1500 | |||||

Production Process

Company ProfileFAQ

1. Which material Grand Heavy can supply?US: ASTM A128/A532 Australia: AS2074 H1A/-H1B British: BS 3100/ BS4844 German: GX 130 MnCr South Africa: SABS 407 Type 1 & 2 Japan: SCMnH11 China: GB/T 5680-2010 Supported by a wide range of alloys Austenitic manganese steels 13%MN, 18%MN , 22% MN MN13CR2, MN18CR2, MN22CR2 MN13CRMO MN18CRMO MN22CRMO High chromium white cast irons Chrome 15%, Chrome 25%, Chrome 30% Cr-Mo alloy steel2. What do you manufacture there?Our company is specialized in producing high-manganese steel, alloy steel, high chromium cast iron, carbon steel, heat-resistant steel and other castings.3. How large is your facility? Which types furnaces do you have?Our factory has over 40,000 square meters and warehouse 10,000 square meters of ready-to-ship and customizable patterns for casting. We use two 5 ton induction furnaces and the maximum melt is 14 tons. We are planning to increase the melt capacity in the near future.4.What temperature is the casting when it enters the heat treatment furnace?- All castings go through a cooling phase which takes from 48 hours to 120 hours depending on the thickness of the castings. For example, our C200 plates are about 300 mm thick, so they have to cool down for at least 100 hours. - Each casting has a process sheet that lists the related requirements, including cooling time.5.What information do we need to provide to you in order to confirm our parts order?We work with technical drawings for any non-standard products. If the order is for standard parts, you only have to provide us with the part number, so we may define the parts of the order.6.How long does it usually take for me to receive the goods?We can guarantee to ship our existing crusher wear parts in less than 2 weeks and you need to know the main factors which affect the lead time as below:a. Customization or notb. Order quantityc. The speed of customs clearance and logistics7.How do you deal with quality problem?We adhere to 'To be your best partner' improvement principle since our foundation. Every single product is precisely checked and well packed before shipping. If some thing goes wrong when you use our products, please send us pictures of the wear part and the machine. This can help us to check out where the trouble is. If it is a quality problem, we will compensate you and do some thing correspondingly to avoid the same problem next time. If the problem is due to misuse, we will provide our technical recommendation for your reference.