- Jaw Crusher Spares

- Symons Jaw Crusher Spares

- Metso Jaw Crusher Spares

- Sandvik Jaw Crusher Spares

- Cone Crusher Spares

- Symons Cone Crusher Spares

- Metso Cone Crusher Spares

- Sandvik Cone Crusher Spares

- Gyratory Crusher Spares

- Symons Gyratory Crusher Spares

- Metso Gyratory Crusher Spares

- Machine Bronze Parts

- Auto Water Pump Fittings

CNC Machining Machined Machinery Machine Metal Copper/Brass/Bronze Parts

Basic Info

| Model NO. | Injection Moulding 01 |

| Condition | New |

| Certification | ISO9001 |

| Standard | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized | Customized |

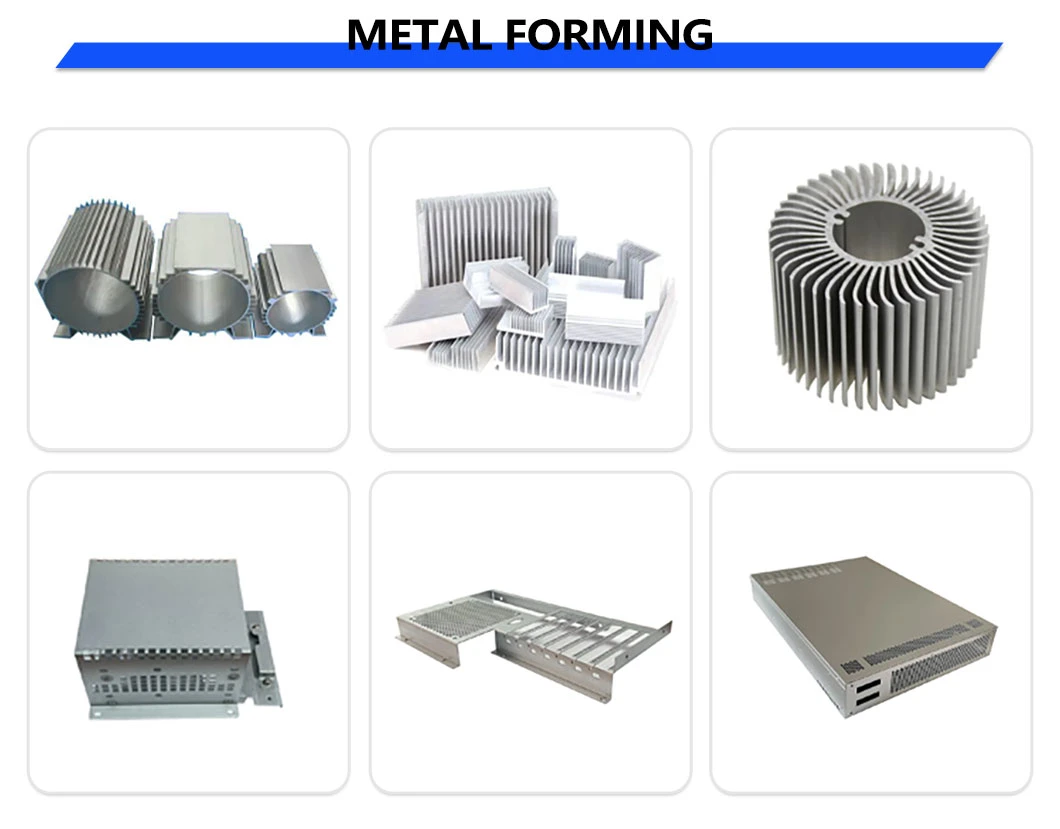

| Material | Aluminum |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Processing | CNC Machining, CNC Milling,CNC Turning |

| OEM/ODM | Yes |

| Drawing Format | Solidworks,PRO/Engineer,Auto CAD,Pdf,JPG,Dxf,Igs,S |

| Production Type | Mass Production |

| Transport Package | Carton, Pallet, Blister Box, Pearl Cotton Board |

| Specification | Customized |

| Trademark | Yu Yang Precision |

| Origin | Foshan, Guangdong |

| Production Capacity | 100, 000 CNC Machining Parts |

Product Description

Product Parameters

| Item | OEM Service Tight Tolerance Custom Design Precision CNC Machining Parts |

| Size | Customized, according to drawing |

| Technological Design | Process analysis and review of product drawings; Draw up a processing plan; Compile process specification and design and manufacture of process equipment |

| Material | Carbon steel, Stainless steel, Aluminum, Aluminum alloy, Copper alloy, Galvanized steel sheet, Magnesium alloy, Titanium alloy, Special materials, Engineering Plastics… Or Customized |

| Tolerance | +/-0.002mm, 100% QC quality inspection before delivery, can provide quality inspection form testing equipment |

| Processing | Milling, Turning, Drilling, Planing, Fitter, Boring, Grinding, CNC machining, Broaching, Grinding and Honing |

| Heat Treatment | Normalizing, Annealing, Tempered, Aging, Tempering, Quenching |

| Special Processing | EDM, Wire EDM, Electrochemical machining, Laser processing |

| Equipment Support | CNC Machining Center(DMG/MAZAK), CNC Turning Milling Compound Machining Center(DMG), CNC Lathe (STS/Feeler/MAZAK/TAKISAWA), Slow-feeding Wire Cut Machine(SODICK), High Speed NC WEDM Tool(San Guan/Gao Cheng),Milling Machine(GENTIGER/Joint), Grinding Table(Jian De), Surface Grinding Machine(NAGASHIMA/Wang Pan) |

| Surface | Polishing, Sandblasting, Zinc plating, Tin plating, Nickel plating, Gold plating, Silver plating, Copper plating, Alloy plating and Spraying (Painting and powder spraying), Anodizing and electrophoresis, etc. |

| Testing Equipment | CMM (ZEISS/HEXAGON), Roundness Meter (ACCRETECH), Tensile Tester (AIGU), Profilometer (TOKYO), Altimeters (TRIMOS), Hardness Tester (HAIBAO), Microscope(EASSON), Marble Platform(XINLEI), etc. |

| Min Order Quantity | 1 piece |

| Supply Ability | 100,000 CNC machining parts, 3,000 Sheet metal parts, 50 Module per day |

| Quotation Against | 2D drawings (PDF, JPG, DWG), 3D drawings (STP, IGS) or sample |

| Payment Term | T/T, L/C, D/P, D/A |

FAQ

Q1:what are our machining equipments?

YY:Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on

Q2:What's kinds of information you need for quotation?

YY:You can provide 2D/3D drawing or send your sample to our factory. then we can make according to your sample

Q3:Can we sign NDA?

YY:Sure. We never divulge customers' information to anyone else

Q4:What are the Advantage of your gears and parts?

YY:Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance

Q5:Delivery time?

YY:Ifin Stock:around 3 days after payment. Mass production:around 20-25 days after receipt of deposit(Accurate delivery time depends on specific items and quantities)

Q6:How about the transportation?

YY:You can choose any mode of transportation you want, sea delivery, air delivery or door to door express